-

Posts

24 -

Joined

-

Last visited

-

Days Won

4

Dishrack last won the day on December 29 2020

Dishrack had the most liked content!

About Dishrack

501st Info

-

Name

Jon

-

501st ID

50524

-

501st Garrison

Knightfall

- My Costume Profile

Profile Information

-

Location

Melbourne

-

Interests

IG @greedogram

Recent Profile Visitors

549 profile views

Dishrack's Achievements

-

Jesse has updated the files too, so they're a bit more forgiving than the ones you and I used, Allan. Probably not worth reprinting it though 🤔😅

-

No worries at all. It's good to have some motivation to get back into it. I used Dupli-Color automotive spray paint. In Australia, the colour is called Holden Black Metallic, but Holden likely translates to General Motors in other countries. The colour code is DSH101. The eye lenses are from LED downlights, specifically ones that had three LEDs for that triangular pattern. I picked them up as spare parts from https://au.rs-online.com/ but they don't seem to stock them anymore. You could probably buy the lights from hardware and butcher them for the lenses but it might be pricey? Hope that's helpful.

-

Hey mate, great to see you're back looking at this. I've not updated my thread for months but really should get around to it. For the pistons, I tried using the ones from the jesse_m files but without being able to get the inside super smooth, things kept catching. I ended up buying an aluminium tube and rod and then printing the rings to go on the outside. I'll get some pictures and post it when I can. The shoulder bearings were a PITA too but did manage to make some based on this design on Thingiverse: https://www.thingiverse.com/thing:4875708 - I had to mod it a fair bit to get it to work though but I was happy enough until I broke it..need to print more of those 😅 No plans to sell the rubber feet as it costs a small fortune to make them and they're not good enough to sell in my opinion. I need to go back to the drawing board on these. The idea is there but my execution was trial and error. Be careful with the rubber shorts as the CRL requires them to be made from a hard material (even though C3PO only had hard shorts in ep.IV and rubber in every movie after that but we're not really building C3PO, are we ). I've been experimenting with casting them in a rigid polyurethane - same material old car bumper bars were made from. It's hard to the touch, but impact resistant. Kinda makes me want to go back and cast the whole costume the same way for longevity. Again, I must get around to taking some more photos and updating my build thread. Thanks for the nudge

-

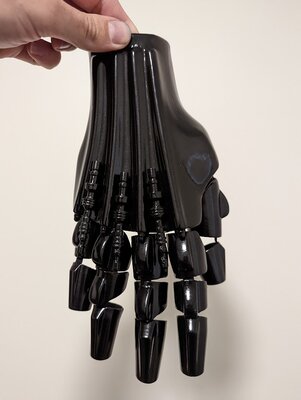

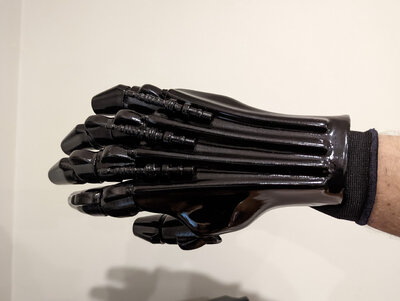

Owing to some nicer weather here - however fleeting - I got back outside for a bit more sanding and painting. After several frustrating and futile attempts to hide the join lines on the leg parts, I shelved them in favour of a quick win: Hands. In order to maintain maximum dexterity without fear of the fingers falling off, I have suspended each digit on elastic attached back to the hand plate. I also added Velcro to the back of the hand plate and the underglove to hold it in place, however this has proved unnecessary and honestly bothersome as it holds the hand in place too well. I think I'll get away with the cuff of the arm keeping the hand plate in place. A small update but good to be back at it.

-

Yeah, you'd think that but here we are ? I'll find my way back to this project over the end-of-year break and keep you updated.

-

Dishrack changed their profile photo

-

With concern about how I was possibly going to fit my foot inside the rigid print, let alone walk without it flexing and snapping, I decided to slush cast the feet in flexible urethane. I'd never worked with urethane or silicone before so a bit of YouTube watching set me on my way. I know there are more experienced builders here, so some of my mistakes will be glaringly obvious to you, but I'll explain my process all the same. Starting with the sanded print, primed and painted in cheap gloss paint (that was actually a dream to work with compared to the top coats I've been using on the other parts), I glued the foot to some scrap melamine board and built a wall around it with my childhood LEGO bricks, hot glued in place (Oh no, not the kragle!). I knew I wanted to create a reservoir for the excess urethane to pool in during casting, so I sealed the ankle with a balloon. My rationale was that it could be inflated to the exact size to create an airtight seal, whilst its dome shape would create a bowl in the inversed-mould to catch the surplus urethane. Next, I covered it in plaster bandage and gypsum for strength, and let it set. When I pulled the silicone mould out of the plaster however, something wasn't right. What I didn't account for was a chemical reaction between the rubber of the balloon and the silicone I used for the mould. Where the silicone contacted the balloon, it didn't cure, instead turning into a gluggy paste that spoiled the end result and was still tacky to the touch. Fortunately all the areas that are affected will be covered by the shin piece, so I decided to proceed. For the tint, I made up some test swatches using a combination of metallic powder and opaque gel to get a colour close to the paint on the other parts. Using a small silicone cupcake mould, I tried the following combinations: 1. Just metallic powder mixed in urethane 2. Just opaque gel mixed in urethane 3. A mixture of powder and gel mixed in urethane 4. Brushing the powder into the mould first and pouring in untinted urethane 5. Brushing the powder into the mould first and pouring in gel tinted urethane #3 gave a result closest to the paint, and so I proceeded. To avoid the urethane spilling out during the slush process, I applied some orange Playdough around the edge to create a lip on what was otherwise just a flat area. This gave a watertight seal and was easy to remove after the urethane had set. Tonight, I pulled it out of the mould. It's black, it's glossy and it's flexible. For a material I'd never worked with, I'm pretty happy with the results. I imagine I'll still need to slice the urethane down the back of the shoe to be able to get my foot in, with the urethane ultimately glued onto a flat deck shoe. Alright, now that you've all seen my mould technique, what should I do differently for the other foot?

-

Nicer weather has given me a couple of opportunities to progress with painting. "You probably didn't recognise me because of the red arm" ... or lack of arms. I enjoy that the metallic base under the gloss layer gives a slightly grey tone in certain light, consistent with how Triple Zero changed between grey and black in different frames of the comic. The perfectionists will see the orange peel; I just see my reflection and I couldn't be happier given this was 3D printed. Overall, very happy with how the paint turned out. Definitely some inconsistencies between cans/batches though but overall everything matches closely enough. Next focus will be the arms.

-

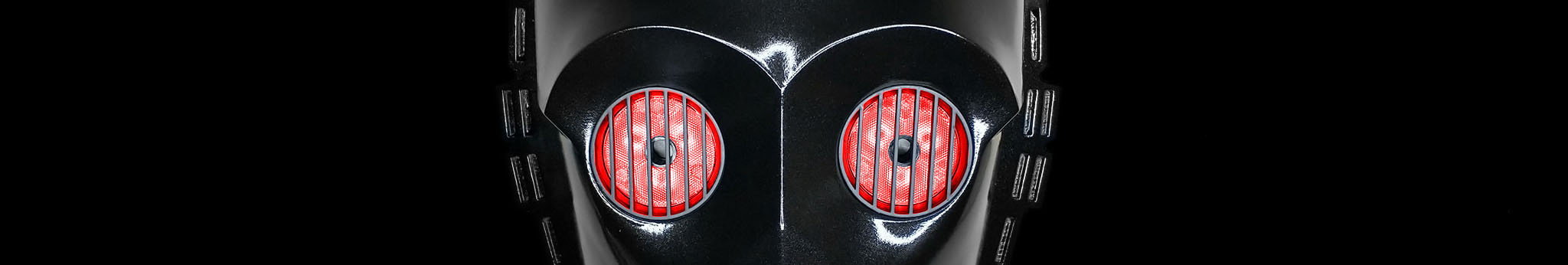

We've had some nice weather in my part of the universe and I got some painting done. Quick question about the CRL: Should the vertical eye slat coverings be black or silver? The text doesn't specify the colour other than a general statement of "armor parts are gloss black", however the photo displays silver coverings. Is this correct and/or a requirement? Not invested either way, just want to get it right.

-

Unsure whether to go with C3PO's "That’s funny, the damage doesn’t look as bad from out here", or Han Solo's "She may not look like much, but she's got it where it counts, kid". Either way, I'm happy to report that all major printing is complete with only a handful of pistons/greeblies to go. Parts are at various stages, with some untouched, others sanded/primed, some have been fiberglassed on the inside for strength and others have been completely painted (not that you can tell here; the black paint looks just like the raw print). Fair to say if you can see a print line or glue seam, that part hasn't been sanded yet as I plan to leave no trace that this was 3D printed. Honestly, I'm happy to be moving to the next phase of bringing everything to life. Heaps of preparatory work to go and still waiting on some specialty hardware to arrive over the next couple of weeks but it's coming together. Next will be the full test fit for mobility. I plan to cast the feet in flexible urethane eventually too.

-

After a few months away from it, I've finally found my way back. I had been sanding parts in my lunch breaks but once winter hit here, being outdoors wasn't viable. That also hampered resin, fiberglass and painting efforts. I have had a chance to process a few parts this week due to a brief break in rain. I've also tweaked the legs and started the long journey of reprinting them, as I wasn't happy with the fit previously. All things considered, I should be done printing all large parts by the end of next week with only some small greeblies to go after that. I had accidentally printed two left shoulder bells (or was it two right shoulder bells? I get them confused all the time) so I used one of them as a test piece for paint. Overall, fairly happy with the outcome. Hopefully there will be a more steady stream of updates from here.

-

Oh no, you've caught me! I don't have much of an update, I'm afraid. Things have stalled slightly due to life circumstances. That said, I have sanded and prepped some parts. Reprinted others. Essentially I got stumped by the shins which are going to need heavy modification. Rest assured, I'm still very much committed to finishing this and will be back on track as soon as I can. Sorry for being a slowpoke!

-

Why yes, there is! Good timing ...a month since my last update and a bit has happened. Printed the shorts in a number of pieces and glued together. I'll keep these as front and back pieces and attach them with elastic to allow the two halves to stretch apart during donning and doffing. These fit surprisingly comfortably and provide support in, uh, all the right places. They were tricky to glue/tack together because of their size and shape. Traditional clamps didn't provide enough three dimensional support so I employed the use of straps from my roof racks to provide cross-axis tension. Next came the dreaded thighs. I've been following a lot of protocol droid builds and the legs seem to be consistently regarded as the hardest bit to fit correctly. The issue being that unlike most armoured costumes, the knees on this are hinged together so if the thigh is too long, the knee isn't in the right spot to bend. Accordingly, this is the first piece I've had to skew to fit. It's about 4% shorter than it is wide. Not a huge different to look at but certainly a huge improvement to wear. It's also a really big piece so again, split it into three pieces. As you can see, it's pushing the bed size of my Ender 3 to the absolute limit but we got there. Here's the final thing which is huge. This alone has around 100 hours of print time in it. Those of you with sharp eyes might notice that even though I said I printed it in three pieces, it's actually in four pieces. Well, that's what happens when your bed is held down by a handful of rare earth magnets and the print catches on the extruder causing the bed to slip, 25 hours into a 30 hour print...No way was I letting that go to waste so reprinted just the top bit and attached it, thus four parts all up. And here he is so far! Triple Zero taking shape as the months tick by. I couldn't be happier I've also replaced the screws that held the head together with the now spare rare earth magnets. This means that I can just snap the bucket on/off as needed without having to awkwardly unscrew the toggles (before and after pics below) Next we keep pushing on with the legs. Phew!

-

Probably won't get back to this until next year so thought I'd close out 2020 with a progress marker for my own records and a bit of forum spam. Upper body now printed (re-printed in some cases, after upscaling) but arm greeblies and pistons still to be added.

-

Thanks for the advice on fibreglass and resin. I'll look into that down the track. It's certainly been a rough fortnight with a bit of personal injury and property damage but let's see what I actually managed to achieve on the costume...not much! I've drilled out the centre of the eye lenses (posted previously) to accommodate the tube that I'll actually be looking through when wearing the costume. I designed a backing piece for it to fit the three red LEDs in each eye. It came out pretty well. Unfortunately the eye holes don't line up with my eyes but I'm investigating a sort of periscope arrangement inside the mask. I've bunged in some 3mm red LEDs but haven't wired them yet. Still, they look plenty menacing even when not illuminated. Test fitted to the mask (without LEDs) Certainly taking on the protocol droid look that we're all familiar with. I wish I had more to report but hopefully my run of bad luck is over and this week will yield better outcomes ?

-

Thanks for the advice - I really appreciate it. The overwhelming advice from my garrison mates is that fiberglass is the way to go. I think it'll be a combination of internal cover strips and maybe one or two layers of fiberglass as I don't want to add any more bulk that I've already got.