Leaderboard

Popular Content

Showing content with the highest reputation since 10/03/2025 in all areas

-

4 points

-

Hi everyone, sorry I'm not very active on the forum, but work leaves little time for Star Wars. The IST costume itself is progressing slowly. I've also prioritized the color change for the AT-AT commander's armor but, in the next days, I'll resume roughing out the IST pieces and I should receive the jacket and pants. I'll post the assembly progess as soon as I have it, while consulting the threads of those who have already made this costume, so as not to make any mistakes. (Don't mind the colors on the chest armor, I used it to experiment on the commander)3 points

-

Received GML clearance , just to wait for the admin stuff to get done and then request full access Then V2 lol3 points

-

gonna try my best to log everything in order. im slowly working more and more on the kit during the weekends as its my only availability right now. ive been sanding and filling this helmet the entire time. got the last round of sanding and hit it with black paint. some areas are needing to be fixed but that is completely okay. once i have all the pieces i need to be black i will hit everything with 2k gloss along with the help of a local star garrison friend. Jim notified me last night my undersuit was ready to be shipped so i paid off the rest and it is now on its way. very excited to get it done Up next. we finally, got the 850 kit in. now some things to address. i was unaware they were gonna trim some of it as a favor. at first glance i was very confused until they reached out a couple days later. not all of the pieces are PLA printed, it is all in fact resin, which means i would have to fully paint the entire armor set to match. the backplate they did do the hard part for me so i now have to clean it up entirely and fix a corner. i was missing a back side wing so i am being sent extras as we speak. the thigh connector parts were looking a little rough with the mold so i kind of left it alone for now until i work on it more. looking at it all was a bit overwhelming but yeah, i worked with what i got. Sunday was the 501st armor party. the host was great for giving advice on how to cut and trim excess materials. it took about almost 4 hours to cut everything as much as we can. next we're gonna have to clean up the rest we can with belt sander to get it all fine and trimmed and then we can glue everything together for assembly.3 points

-

After emailing 850 and having to put my foot down, i finally got the shipping notice that it’s on the way. Hopefully it’ll be here next time in time for the 501st armor party I’m attending3 points

-

2 points

-

Yay, I have officially been approved by my GMLs! TX-12657 reporting in! I may yet have further modifications to make for troopability so this thread shall continue. The next thing on my list is to start working on an E-11D and perhaps a DLT-19D as well. I have bought the files for all three DT blasters from MCM, and have already started printing. That's all for now.2 points

-

Got to take the death trooper out for a zoo troop and see how it did. Lots of fun, and lots of things to fix. First off, the cooling vest suggestion was a life saver in tandem with some big ol’ fans in my bucket. I was actually reasonably comfortable for the troop. The first big issue though, was my ability to walk. As you can see in this picture, my leg armor is touching, no good there. That is getting further trimmed. Second, my helmet pressed on my nose which was not immediately obvious to me that it would be an issue, until of course I was light headed and out of breath. I have modified my padding so it sits higher, and furthermore does not rest on my nose at all. Still waiting for official approval from GMLs but I have plenty I can work on in the meantime time. Thanks all for the help so far!2 points

-

Greetings. I'm brand new to cosplaying, but I've always wanted to build some Star Wars outfit. I naively decided to make a Death Trooper outfit. It's just black right? 😝 I bought some STLs for the helmet, armour and a E-11D Stormtrooper Blaster from GA and started printing. I'm printing the parts on a Voron 2.4 350 using ABS and a layer height of 0,12mm, so that I can reduce the layer lines a bit. So far, I've printed the top of 1/2 of the helmet and the mandible and I'm busy printing the sides and the back. I saw an interesting technique called vapour smoothing, which I want to try, but I'm willing to "Learn to Love Sanding™. Any tips, tricks or other advice will be much appreciated.2 points

-

Looking good Trooper. Yes, the DT is a very warm and motion limiting armor kit. I have fans in my helmet; Additionally, I used a construction helmet liner to provide more air flow around my head. Most people complain about the range of motion in their upper legs and pinching between the thigh armor and cod piece. You can make the gap bigger between the thighs and cod piece by determining how much of a gap you need and trimming that amount off the top of the thighs. When you trim the top of the thighs, follow the shape all the way around so the appearance of the thighs shape remains the same. If you are getting binding or limited range of motion in your knee area, you can cut an additional amount off the top of the thighs and raise up the thigh armor, this will increase the knee gap enough to allow for a greater range of motion. I am not sure how your torso armor is strapped but if you are having issues turning your upper torso, a way to increase the range of motion is to have the chest and back separate from the lower back and abdomen armor strapping. This will allow your upper body to twist and the lower armor to stay in place. Issues occur with the helmet hitting the neck collar in the back when looking up. There is not much to do about that other than either making sure the collar is as close to your neck so that the helmet opening allows the collar to rise into the helmet opening. Or you can trim the neck collar's edge down some to give you more of a gap. It took me almost twelve troops and experimentation to get all my armor strapped and sized so it gives me enough freedom of movement to walk up and down stairs, climb onto parade trailers, and be able to actually sit down. Even to this day I am still tweaking mt DT set up. Shins, if clam shelled, definitely need a locking type closure. I use Velcro along the vertical split on mine and it works perfectly.2 points

-

Hi Chris, We will get together to get this sorted for you. Please be patient & we will have you sorted as soon as we can arrange the meetup. Thanks2 points

-

2 points

-

2 points

-

It is something we'll need to do on the backend via the Holocron. I'll get with @Dropkick and @BlacXabbath to show them how to do it. We were supposed to do it a month ago but my wife passed away, so Legion kind of took a back seat.2 points

-

Update! I was able to repair my back plate using mold-able epoxy putty and even get back some of the lost details in the corners. It is definitely not perfect but I'm thinking it should hopefully be good enough at least for basic. Also, my assembly of the shins has seemed to work out pretty great and those are now almost done (aside from the bottom flaps). I also went and painted almost everything in gloss black, except for the thighs which I am still assembling. Almost all the bits are painted now and currently drying/curing. Then I can go in with the metallic black on the details. I will need to decant some into a bottle so I can brush on the fine details like the grooves and such. I have started getting things strapped as well. The chest plate goes together in four places with velcro at the armpits and shoulders by the collar, which I think is looking good, what do we think?2 points

-

2 points

-

2 points

-

Any time and you're most welcome. I have a hard hat liner in my DT. It allows a lot more airflow that thick pads and makes aligning my eyes with the helmet visor easy. Here is what the inside of my helmet looks like: Here is a video on how to do it. It is using a TK helmet but the principle is the same. This was done my Trooperbay. And as I was looking for Trooperbay's video I found this one by Captain's Wookshop which he did for his DT Hope this helps.1 point

-

Thank you for your very thorough response! I will look into the linked thread below and I think I'll refrain from adding any lifts in my boots to keep from being uncomfortable while trooping. I'm glad to hear that folks who are 5' like me are still intimidating haha. Oh one more question for now, do you know any of resources or information on what to add to the helmet for padding/fitting it well? Thanks.1 point

-

1 point

-

1 point

-

we need to swing back around to it. Been busy with the Tactical Agent and Del rewrites.1 point

-

1 point

-

Got it. I have a PDF file template I got from you that I am followed for the detail shots. I should have all of those (minus V2 and weapon stuff) ready to go and the document is good. I was more worried about how to upload the PDF itself. I did realize in prepping all of this that I forgot my action pose. I am trooping tonight so I'll get a shot from that and upload hopefully later this weekend.1 point

-

Thank you very much ! I can't wait to wear it and I'd like to see a lot of troopers with this armor ^^1 point

-

Looking forward to seeing this bad boy as a new kit in the group! Crossing my fingers for you bro on this kit! It is one I would LOVE to make myself!1 point

-

Cheers Shane. Been a long long road but getting there. Now to get back to the armour lol1 point

-

Hey Dan, apologies for the delay, work has been crazy, I've been flying my ass off. For your Specialist L2 application its good that you have taken new sets of pictures. Here is what we will need by way of photos. 1. Standard set of photos for basic approval: Front: arms down - palms inward, arms up parallel to the ground - palms down Right side: arms down - palms inward, arms up parallel to the ground - palms down Back: arms down - palms inward, arms up parallel to the ground - palms down Left side: arms down - palms inward, arms up parallel to the ground - palms down Some type of action shot with a weapon or using your hands like in a fist or "force wave" 2. After you take the basic photos you will need to take photos of each of the L2 requirements that are mentioned in the CRL example, if the L2 Requirement says "There are two small notches on the outer ⅕ of each side of the canister approximately 3/4" (20mm) from the inner edge of the end caps and spaced approximately 1" to 1.25" (25-30mm) apart on the lower edge of each horizontal grooves. Refer to reference photos for specific details." then we would need a close up photo of the detail with a ruler next to the detail to verify the detail and measurements. If an L2 requirement is visible in the basic photos or in another close up, you don't have to take an up close photo. 3. If you have Microsoft Office you use Word or PowerPoint to insert all your photos and then save the file as a PDF and upload that into your Application thread. If you can't do that, then it would be best to create an account on an image storage site. Imgur is what I use. Create a post and upload all the photo to there and post the link in make it shareable in your Application Thread in the Specialist sub-forum. 4. Make sure all your photos are clear, well lit, and in at least 960 or larger resolution. Let me know if you have any issues or other questions. You can go to any of the request threads for examples.1 point

-

1 point

-

1 point

-

Sure! I was a little confused figuring it out as well. Here’s the right thigh: The long side has a little detail and the short side sticks down. Left side: Long side is smooth with no detail, Short side is level at the bottom, and gets one of the little box greeblies on it. I glued all sides butting up against the front and overlapping the back based on what I could see in the CRL photos.1 point

-

Also ich bin zu allem bereit und meine Rüstung ist fertig und Tragbar, Sie war ein riesen Erfolg bei der German Garrison in Speyer und warten alle gespannt auf meinen Eintrag ;-)))) Wenn ich einzel Fotos für die Crl machen soll braucht ihr es nur zu Sagen in welcher größe und Auflösung LG Andreas1 point

-

Armour fits a lot better. Can now get in it with the mpsb straps and buckles with loads of overlap at the side. So need to clean with degreaser and then sort out the picture hooks to secure the horn fronts , glue straps at back , then Velcro on the buckle and chest. Still a ways to go but getting there with the v2 once the above clears1 point

-

Any update on this? They've already transitioned the CRLs to the new web format. However, the "Imperial Security Trooper - Andor - CRL Discussion" thread is still closed. Is the moratorium still in effect?1 point

-

For the heat, do you have fans in the helmet? That's a must. For your torso, you may have to invest in an ice vest to help keep cool. I did and it definitely helps take the edge off. I got mine from Polar Products brand and it came with 9 reusable ice packs. Depending on how hot it is and if you're inside vs outside, they can last a few hours.1 point

-

I have been following along in the FB messages and I am so sorry for your loss. I actually posted the request there to have another set of eyes as I knew you had a lot going on. After looking at @Andreas Funk's photos and videos, his armor may make the mark for the CRL so we may not have to wait on someone to build a kit and this CRL approval may go quickly once we get the wording completed. I am still building mine with 3D FDM and Resin printers so its taking a while. Plus once I get mine finished I will have to figure out how to send it back to the USA when I leave my job. Good to see you getting back into things, if you ever need anything send me a message.1 point

-

You may find this guys' 3D printed Death Trooper build videos helpful. He used the MCM Designs files for his kit. It helped my build a lot:1 point

-

lol, I'm busy watching M.M.'s Prop shop, and she just mentioned her foot sander. I'm going to try the ABS slurry post-processing first and if that fails, go through the multi-stage sanding steps. Here are the side and back pieces of the helmet.1 point

-

Thanks, I missed out the E+D, but luckily I bought the correct STL. I thought it was all going to be shiny black when I purchased the STLs, but then saw it was more than just glossy black, so that comment was more tongue in cheek.1 point

-

Welcome Rudi. you have picked a great costume. Take your time and ask lots of questions. for vapour smoothing, It looks like a neat technique but from what I have seen, you will still need to sand some. I have recently seen people using Bondo/Acetone wash that is painted onto the armour. It appears to do a great job smoothing out the print lines but will affect fine detailed areas. Thankfully, the death trooper does not have a lot of fine details except for around the muzzle. I recently purchased an electric foot sander from Amazon. It is a small circular sanding disc and it makes sanding so much easier for larger areas. I look forward to following your build.1 point

-

I am using rustoleum painters touch 2x cover gloss black paint+primer on everything. There are nicer options out there but I’m cheap and I was able to achieve a result I am pleased with. I have been told the rustoleum high performance cans deliver a much nicer finish. That being said, I have not used a clear coat and since I plan to weather my armor, I am not worried about a perfect finish anyway.1 point

-

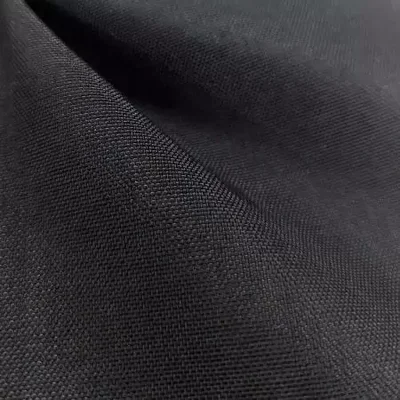

Hi Dennis, thanks for the feedback. It's definitely important to give people as many options as possible while staying true to the references, so that's what we want to do with the vest too. I fully agree that the weave on the vest is slightly wider than that in the flightsuit. Just a quick reminder of the new text we currently have in draft form: "The tactical vest and its pouches are made of black fabric similar to the flight suit material. Heavy black canvas is recommended. " It's important to note that we're not saying that it has to be the same material as the suit, just that it has to look quite "similar". As you show in your picture above, the Cordura already looks extremely close to canvas, so would be 100% acceptable for both basic and Level 2 clearance under the newly proposed text. I wouldn't like to specifically name the Cordura brand as a possible option in the current text, just in case people get confused and think the flightsuit should be made from that material too. However to make it even more flexible, what about the following small tweak? "The tactical vest and its pouches are made of black fabric similar to the flight suit material. Heavy black canvas or similar fabrics are recommended. "1 point

-

1 point

-

Ill pm you Matt, I want to keep this topic on track. We will develop a vendor list. Theres only a couple I know of .1 point

-

Helmet bolts on! @RAIDER, do you have anymore edits you'd like to see?1 point

-

This just in today: https://www.instagram.com/armoryshop_official/p/DPMfw7GiMr7/ This was followed up by a post advertising a Phase 2 Cody helmet. So, It's unclear if they will begin producing the kits they did prior to the shutdown. It seems as though they'll now be known as "RAWWWGEMS Studio." "The forge is relit. A new dawn for our studio. Hey everyone. It’s been three years since you last heard from us - and that’s a long silence. We owe you an honest explanation. I’m Artem, the new owner of this studio. When I stepped in, I didn’t realize how many unfinished orders and unresolved problems were left behind. Some of you never got the helmets you paid for. Finding that out was tough, and it’s not how I imagined starting this journey. Over these years, my small team and I kept quiet because we wanted to focus on the work. We’ve been improving our painting, getting better at casting, and pushing our 3D-printing to the next level. We didn’t want to come back with words - we wanted to come back with results. We can’t change the past, but we can make it right. Everyone affected will be part of a compensation program with big discounts on our new products. That’s our promise. This isn’t just a business for us. We love creating helmets and props from Star Wars and other worlds - and now we’re starting fresh under a new name that reflects that passion: RAWWWGEMS Studio The workshop is alive again. New projects are already on the way, and we’re excited to finally share them with you. Thanks for sticking with us - the journey continues."1 point

-

Sorry been super busy at work the last few, if you still need pictures of the strapping I can get them next weekend, in other updates my armour arrived from imperial surplus so will be getting that together soon1 point

-

I will also send my Binoc photos, on the outside they look great, I believe the width needs enlarged some.1 point

-

I just heard back from Jim on my own L2 level tac vest , its a change to how he has produced them in the past. Its looking really good and once I have it in hand I will share on my own WIP.1 point

-

1 point

.thumb.jpg.9f1c38be7d684bade26a2c3cbbebbb81.jpg)

.thumb.jpg.b14209ff3bd68636da46a33fb329e081.jpg)

.thumb.jpg.4b7f118dc6c023f5a5030ef2f1a3fe15.jpg)